Table of Contents

▶In This Guide

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

- 11.

- 12.

- 13.

- 14.

- 15.

Concrete Flooring Specialist for Your Dream Space

A concrete flooring specialist is a trained professional who designs, installs, and finishes decorative and functional concrete floor systems for residential and commercial properties. These experts specialize in techniques including polished concrete, stained finishes, epoxy coatings, and decorative overlays. A qualified concrete flooring specialist assesses substrate conditions, prepares surfaces through grinding and leveling, applies chosen finishes, and ensures proper sealing for durability. They understand concrete chemistry, moisture mitigation, and design aesthetics to create floors that combine functionality with visual appeal, typically completing projects within 3-7 days depending on complexity and square footage. This is often the first step in our flooring installation process. Find concrete flooring contractors near me for your project.

When you walk into a space with stunning concrete floors, you're witnessing the artistry of a skilled concrete flooring specialist. These aren't your grandfather's cold, gray garage floors anymore. Modern concrete flooring has evolved into a sophisticated design choice that combines industrial durability with refined aesthetics. Whether you're renovating your home, designing a commercial space, or building from scratch, understanding what a concrete flooring specialist does—and how they can transform your space—is essential. In this guide, you'll discover everything about concrete floor systems, from the various finishing techniques available to the installation process, cost considerations, and how to choose the right professional for your project. We'll break down the myths, share insider knowledge, and show you why concrete might be the perfect flooring solution you've been searching for. Our experienced concrete contractors specialize in flooring installations. For professional floor work, consider our concrete floor contractor services.

What Does a Concrete Flooring Specialist Actually Do?

A concrete flooring specialist is far more than just someone who pours concrete. These professionals are part craftsman, part chemist, and part artist.

They assess your existing substrate conditions, identifying moisture issues, structural concerns, and surface imperfections that could compromise your floor. Then they prepare the surface through grinding, shot blasting, or scarifying to create the perfect foundation. The specialist applies specialized treatments—polishing, staining, epoxy coatings, or decorative overlays—based on your aesthetic goals and functional requirements.

Here's the thing: not all concrete contractors can do this work. A dedicated flooring specialist understands concrete chemistry at a molecular level. They know how different aggregates react to polishing, which stains penetrate best in specific conditions, and how humidity affects curing times.

The Specialized Skills That Set Them Apart

Concrete flooring specialists bring technical expertise that general contractors simply don't possess. They're trained in moisture vapor emission testing, surface profile assessment, and pH level analysis—all critical factors that determine whether your floor will last decades or fail within months.

They also understand design. They can show you how to achieve that high-gloss polished concrete finish you saw on Instagram, or create custom stain patterns that complement your interior design vision.

Types of Concrete Floor Finishes Every Homeowner Should Know

The variety of finishes available today is honestly mind-blowing. Let's break down your options.

Polished Concrete Floors

This finish involves mechanically grinding and polishing the concrete surface using progressively finer diamond abrasives. The result? A glass-like sheen that reflects light beautifully and requires minimal maintenance.

Polished concrete comes in various gloss levels—from satin to high-gloss—depending on how many grinding steps the specialist completes. The process also densifies the concrete, making it incredibly durable and resistant to dusting.

Stained Concrete Solutions

Concrete stains penetrate the surface to create permanent color that won't chip or peel. You've got two main options: acid-based stains that create variegated, natural-looking tones, and water-based stains that offer more consistent, vibrant colors.

A skilled concrete flooring specialist can blend multiple stain colors, creating custom patterns and designs that look like expensive stone or unique artwork.

Epoxy and Coating Systems

Epoxy coatings create a protective layer over concrete that's resistant to chemicals, stains, and heavy traffic. These work brilliantly in garages, commercial kitchens, and industrial facilities.

Modern epoxy systems come in metallic finishes, solid colors, and decorative flake patterns. The installation requires precise temperature and humidity control—another reason you need a specialist rather than a DIY approach.

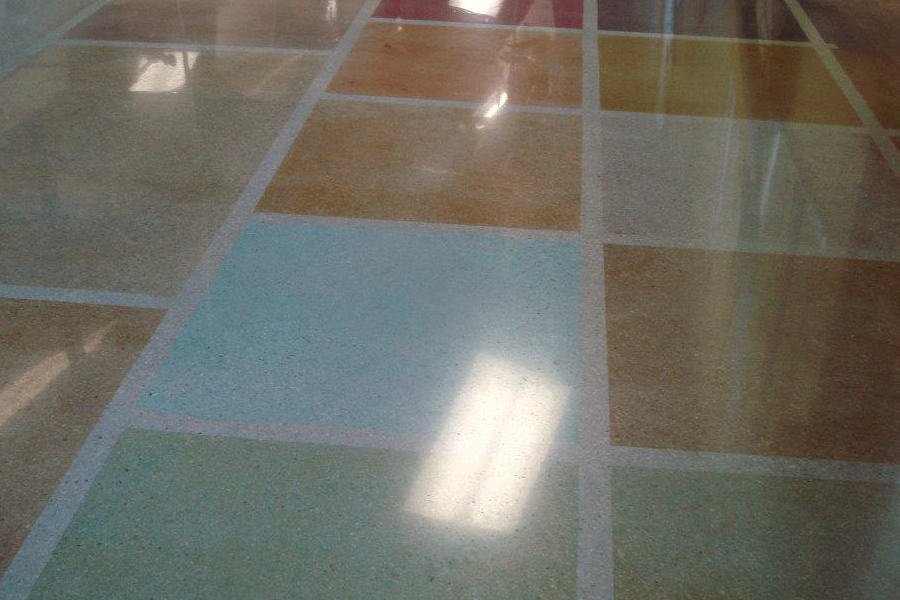

Decorative Concrete Overlays

When your existing concrete is damaged but structurally sound, overlays provide a cost-effective solution. These thin toppings can be stamped, stained, or textured to mimic tile, wood, or stone.

Overlays typically range from 1/4 inch to 3/4 inch thick and bond directly to the existing surface.

The Undeniable Benefits of Choosing Concrete Flooring

Why are homeowners and business owners increasingly turning to concrete? The advantages are compelling.

Durability That Outlasts Everything Else

Concrete floors can last 100+ years with proper installation and minimal maintenance. Compare that to carpet (10 years), vinyl (15 years), or even hardwood (25-30 years). The initial investment pays dividends for decades.

Low Maintenance Requirements

Forget about refinishing, resealing, or replacing. Polished concrete needs occasional damp mopping and resealing every few years. That's it. No special cleaners, no expensive maintenance contracts, no headaches.

Exceptional Indoor Air Quality

Unlike carpet that traps allergens, dust mites, and pet dander, concrete provides a hypoallergenic surface. This makes it ideal for anyone with respiratory sensitivities or allergies.

Energy Efficiency Through Thermal Mass

Concrete absorbs heat during the day and releases it slowly at night, helping regulate indoor temperatures naturally. This thermal mass property can reduce HVAC costs by 15-30% in some climates.

Design Versatility Beyond Your Imagination

The customization options are nearly limitless. Color, texture, pattern, sheen level—a concrete flooring specialist can create virtually any look you envision. Want the appearance of expensive marble without the price tag? Done. Prefer an ultra-modern metallic finish? No problem.

Cost-Effectiveness Over Time

While initial installation might seem expensive, the lifetime cost is remarkably low. You're not replacing floors every 10-15 years. You're not paying for ongoing maintenance. The math works heavily in concrete's favor.

Resistance to Moisture and Stains

Properly sealed concrete resists water damage, making it perfect for basements, bathrooms, and kitchens. Spills wipe up easily without leaving permanent marks.

Eco-Friendly Flooring Option

If you're building new or have an existing concrete slab, polishing or coating that surface eliminates the need for additional materials. This reduces your environmental footprint significantly. Many decorative concrete systems use low-VOC or zero-VOC products, improving indoor air quality.

Increased Property Value

High-quality concrete floors are a selling point. They appeal to buyers looking for modern, low-maintenance homes with designer aesthetics.

Suitable for Radiant Heating Systems

Concrete's thermal conductivity makes it ideal for in-floor heating. The material distributes heat evenly, creating comfortable warmth throughout the space.

How the Concrete Floor Installation Process Actually Works

Understanding what happens during installation helps you prepare and know what to expect. Here's the step-by-step breakdown.

Step 1: Initial Consultation and Assessment

A qualified concrete flooring specialist starts by evaluating your space. They'll test for moisture issues, check for cracks or structural problems, and discuss your design goals and budget constraints.

This assessment determines whether your existing slab can be refinished or if you need a new pour. Don't skip this step—attempting to install a decorative finish over compromised concrete always ends badly.

Step 2: Surface Preparation

This is where inexperienced contractors often fail. Proper preparation is absolutely critical.

The specialist grinds away any existing coatings, removes contaminants, and creates the appropriate surface profile. For polished floors, this involves multiple grinding passes with increasingly fine diamonds. For coatings, the surface needs sufficient texture (think medium-grit sandpaper) for proper adhesion.

Cracks get filled, joints get addressed, and any low spots get leveled. This phase typically takes 1-3 days depending on square footage and condition.

Step 3: Moisture Mitigation (If Necessary)

If moisture testing reveals high vapor emission rates, the specialist applies a moisture mitigation system. Skipping this step when needed causes coatings to bubble and delaminate—an expensive mistake.

Step 4: Application of Chosen Finish

Now comes the transformation.

For polished concrete, the specialist continues grinding with progressively finer diamond pads, then applies a chemical densifier that hardens the surface. Final polishing creates that distinctive shine. The entire polishing process might involve 8-10 different grinding stages.

For stained floors, the specialist applies the stain, allows proper reaction time, then neutralizes and rinses the surface. Multiple stain layers can create depth and complexity.

For epoxy systems, the specialist applies primer, base coat, optional decorative elements (flakes or metallics), and final clear coat. Temperature and humidity must be controlled precisely—epoxy is temperamental.

Step 5: Sealing and Protection

The final step involves applying an appropriate sealer. This protects your investment and enhances the appearance. Sealers come in various types—penetrating sealers that soak into the concrete, or topical sealers that create a protective film.

The specialist will explain maintenance requirements and provide guidance on when resealing becomes necessary (typically every 2-5 years depending on traffic).

Step 6: Curing and Final Inspection

Different finishes require different curing times before you can use the space normally. Polished floors are ready immediately. Stained floors need 24-48 hours. Epoxy systems often require 3-7 days for full cure, though you might walk on them sooner.

Residential vs. Commercial Concrete Flooring: Key Differences

The approach changes significantly based on the space type.

Residential Applications

In homes, aesthetics often take priority. Homeowners want floors that feel warm and inviting while maintaining the modern appeal of concrete. Residential concrete flooring typically features:

- •Warmer stain colors and matte to medium gloss finishes

- •Integration with radiant heating systems

- •Custom patterns and borders in living areas

- •More decorative elements like saw-cut designs or embedded materials

A concrete flooring specialist working on residential projects focuses heavily on the design consultation process, helping homeowners visualize the final result through samples and mockups.

Commercial Concrete Flooring

Commercial spaces prioritize durability and maintenance efficiency alongside appearance. Retail stores, restaurants, and office buildings need floors that withstand heavy foot traffic, resist staining, and clean easily.

Commercial installations often use higher-gloss polishes or more durable epoxy systems. The color palette tends toward neutrals that won't show dirt or scuff marks. And the installation timeline must work around business operations—many commercial projects happen overnight or on weekends.

What Does Concrete Flooring Actually Cost?

Let's talk numbers. Pricing varies considerably based on several factors.

Basic polished concrete starts around $3-$5 per square foot for a simple grind-and-seal. Mid-level polishing with stain or scoring runs $5-$8 per square foot. High-end polished concrete with multiple colors, custom patterns, and premium sealers can reach $10-$15 per square foot.

Stained concrete typically ranges from $2-$10 per square foot depending on complexity. A single-color acid stain is cheapest. Multiple colors with custom patterns cost more.

Epoxy coatings run $3-$12 per square foot. Basic garage floor epoxy sits at the low end. Metallic epoxy systems with multiple colors command premium pricing.

Decorative overlays start around $5 per square foot and can exceed $15 for complex stamped or textured finishes.

Here's what affects the final price:

- •Square footage (larger projects have lower per-square-foot costs)

- •Condition of existing concrete (extensive repairs increase costs)

- •Complexity of design (multiple colors and patterns require more labor)

- •Type of finish selected

- •Your location (labor costs vary regionally)

- •Site access and working conditions

Designer Concrete Palm Beach provides detailed quotes after the initial assessment, ensuring you understand exactly what you're getting and why it costs what it does.

Common Mistakes to Avoid When Installing Concrete Floors

Over the years, we've seen these errors repeatedly. Learn from others' mistakes.

Skipping the Moisture Test

This is the number one killer of concrete floor projects. Excess moisture causes coatings to fail, stains to appear blotchy, and sealers to delaminate. Always test. Always.

Choosing the Wrong Finish for Your Needs

That gorgeous high-gloss finish you love might show every footprint and require constant cleaning. A busy household with kids and pets needs different solutions than an empty-nester couple. Your concrete flooring specialist should discuss your lifestyle honestly and recommend appropriate options.

DIY Installation of Advanced Systems

Simple concrete sealing? Maybe you can handle it. Polished concrete or epoxy coatings? Leave it to professionals. The equipment alone costs tens of thousands of dollars, and technique takes years to master.

Neglecting Proper Curing Time

Rushing the process causes problems. Each step needs adequate time to cure properly. Moving furniture too soon or exposing new epoxy to moisture before it's fully cured ruins your investment.

Ignoring Joint Placement

Concrete naturally cracks as it expands and contracts. Control joints manage where those cracks occur. Trying to hide or eliminate joints through improper techniques backfires.

Using Incompatible Products

Not all sealers work with all stains. Not all epoxies adhere to all concrete types. Product compatibility matters immensely. This is another reason professional expertise proves invaluable.

Inadequate Surface Preparation

Trying to shortcut the prep work to save money or time guarantees failure. Every successful concrete floor project starts with meticulous preparation.

How to Choose the Right Concrete Flooring Specialist

Not all contractors are created equal. Here's how to find someone truly qualified.

Look for specialists who focus primarily on decorative and polished concrete rather than general contractors who occasionally do these projects. Specialization matters.

Ask about their training and certifications. Organizations like the Concrete Polishing Association of America (CPAA) and the Decorative Concrete Council offer professional certifications that demonstrate commitment to best practices.

Request a portfolio showing diverse projects. You want to see residential and commercial work, different finish types, and various design styles. This demonstrates versatility and experience.

Check reviews and ask for references. Talk to previous clients about their experience, whether the project stayed on budget and schedule, and how the floors have held up over time.

Understand their process. A professional will conduct thorough site evaluation, provide detailed proposals, explain options clearly, and set realistic expectations about timelines and outcomes.

Get everything in writing. The proposal should specify materials, techniques, timeline, warranty information, and total cost. Avoid contractors who give vague verbal estimates or pressure you to decide immediately.

Maintaining Your Concrete Floors for Maximum Longevity

Good news: concrete floors are famously low-maintenance. But they're not no-maintenance.

Daily and Weekly Care

Sweep or dust-mop regularly to remove dirt and grit that can gradually wear down sealers. For deeper cleaning, damp-mop with clean water or pH-neutral cleaners specifically designed for sealed concrete.

Avoid harsh chemicals, especially acids or ammonia-based products that can damage sealers. And never use wax—it creates a buildup that dulls the finish and requires professional removal.

Long-Term Maintenance

Depending on traffic levels, plan to reseal your floors every 2-5 years. High-traffic commercial areas need more frequent resealing than residential spaces.

Watch for areas where the sealer shows wear—these appear as spots that look different or feel rougher. Address these promptly to prevent moisture penetration or staining.

For polished concrete, professional re-polishing every 5-10 years refreshes the appearance and addresses any surface wear.

Protecting Your Investment

Use furniture pads under heavy items to prevent scratching. Place mats at entrances to catch dirt and moisture before it reaches your floors. Clean spills promptly, especially acidic substances like wine, juice, or vinegar.

In commercial settings, implement a regular professional maintenance program. This costs far less than premature floor replacement.

Why Concrete Flooring Works Perfectly in Palm Beach

Let's talk about our specific environment. South Florida presents unique challenges and opportunities for flooring.

The humidity here is relentless. Traditional flooring materials struggle—hardwood warps, carpet traps moisture and develops mildew, and some tiles can actually grow mold in the grout lines.

Concrete thrives in our climate. Properly installed and sealed concrete resists moisture beautifully. It won't warp, rot, or harbor mold. And during our hot summers, concrete floors feel refreshingly cool underfoot.

The tropical storm season brings flooding risks. Concrete floors can get wet and dry out without damage—try saying that about carpet or hardwood. This resilience provides peace of mind that's hard to overstate.

Our coastal aesthetic also pairs naturally with concrete's clean, modern appearance. Whether you're going for sleek contemporary or relaxed coastal chic, concrete adapts to your vision.

Designer Concrete Palm Beach understands these local considerations. We've worked on hundreds of projects throughout the area and know how to design and install floors that perform beautifully in our unique environment.

Concrete Flooring for Specific Spaces

Different rooms have different requirements. Let's explore how concrete works in various applications.

Kitchens

Concrete handles the kitchen environment brilliantly. Hot water, spills, dropped objects, heavy foot traffic—it shrugs off everything. The smooth surface makes cleanup easy, and properly sealed concrete resists staining from typical cooking mishaps.

Many homeowners choose a slightly textured finish in kitchens for slip resistance when water hits the floor.

Bathrooms

Yes, concrete works in bathrooms. The key is proper sealing to prevent water penetration. The result is a waterproof, modern floor that coordinates beautifully with tile or stone on walls.

Heated concrete floors make bathrooms luxuriously comfortable year-round.

Living Areas

Open-concept living spaces benefit from concrete's visual continuity. One floor flowing from the kitchen through the living room to dining area creates a spacious, cohesive feel.

You can vary the finish or add decorative elements to define different zones while maintaining overall continuity.

Basements

Concrete is the obvious choice for basements. You already have a concrete slab—why cover it with materials that might fail when moisture appears? Polishing or coating the existing slab creates beautiful, functional space at reasonable cost.

Garages and Workshops

Epoxy-coated concrete garage floors resist oil stains, hot tire pickup, and chemical spills. They're also far easier to keep clean than bare concrete. The difference is dramatic.

Outdoor Spaces

Stamped and stained concrete creates beautiful patios, pool decks, and walkways. The material withstands weather, requires minimal maintenance, and can be designed to complement your home's architecture.

Frequently Asked Questions About Concrete Flooring

How long does it take to install concrete floors?

Timeline depends on the project scope and chosen finish. Basic staining might take 2-3 days. Full polished concrete installation typically requires 3-5 days. Extensive repairs, large square footage, or complex designs extend the timeline. Your concrete flooring specialist will provide accurate scheduling during the consultation.

Can concrete floors be installed over existing floors?

Sometimes. A specialist can install thin overlays over certain existing floors if they're structurally sound and properly prepared. However, the best results come from working directly with the concrete slab. Trying to coat over vinyl, tile, or wood adds complexity and potential failure points.

Are concrete floors cold?

Concrete does feel cool to the touch, which is actually pleasant in warm climates like ours. However, concrete works exceptionally well with radiant heating systems. The material's thermal mass distributes heat evenly, creating comfortable warmth throughout the space. Many homeowners find heated concrete floors more comfortable than traditional flooring.

Will concrete floors crack?

Concrete naturally develops some cracking as it expands and contracts with temperature changes. Properly installed floors include control joints that guide where those cracks occur. Existing slabs being refinished might already have minor cracks, which specialists can address through filling or incorporate into the design as character elements. Significant structural cracks indicate bigger problems that need evaluation before finishing work begins.

How slippery are polished concrete floors?

This depends on the gloss level and whether the floor gets wet. High-gloss finishes are slipperier when wet than lower-gloss options. For areas prone to water exposure, specialists can adjust the finish or add slip-resistant treatments. Properly designed concrete floors meet safety standards for their intended use.

Can I change the color later if I don't like it?

Stains penetrate the concrete permanently, so changing color requires grinding away the affected layer and restaining—basically starting over. This is why working with samples and mockups during design is so important. Coatings and epoxy systems can be recoated with different colors more easily, though surface preparation is still required.

What's the difference between sealed and polished concrete?

Sealed concrete has a topical protective coating applied over the surface. Polished concrete has been mechanically refined to create shine from within the concrete itself, then treated with a densifier and possibly a sealer. Polished concrete typically looks more refined and requires less maintenance than simply sealed concrete.

Do concrete floors work with underfloor heating?

Absolutely. Concrete's thermal conductivity makes it ideal for radiant heating systems. The material absorbs and distributes heat evenly, creating comfortable warmth without hot spots. Many homeowners installing new concrete floors integrate radiant heating simultaneously.

The Future of Concrete Flooring Design

The concrete flooring industry continues evolving with exciting innovations.

New staining technologies offer more color options and better consistency. Metallic epoxy systems create stunning three-dimensional effects that mimic flowing water or molten metal. 3D concrete printing might soon allow for custom textured patterns impossible with traditional techniques.

Sustainability remains a growing focus. Concrete refinishing reduces waste by utilizing existing slabs rather than adding new materials. Manufacturers develop lower-VOC products and more eco-friendly chemicals.

Smart floor technologies are emerging, with concepts like embedded sensors that monitor structural health or regulate building temperatures. While still developing, these innovations might become standard in future commercial installations.

The bottom line? Concrete flooring is far from a passing trend. It's a proven, practical solution that continues improving and adapting to modern needs.

Ready to Transform Your Space?

Concrete flooring offers unmatched durability, endless design possibilities, and long-term value that few other materials can match. Whether you're drawn to the sleek sophistication of polished concrete, the customizable beauty of stained finishes, or the industrial strength of epoxy coatings, working with a qualified concrete flooring specialist ensures your project succeeds.

The difference between disappointing results and a floor you'll love for decades comes down to expertise, proper technique, and understanding your specific needs. Don't trust this investment to general contractors or weekend DIY experiments.

Designer Concrete Palm Beach brings years of specialized experience to every project. We've transformed homes and businesses throughout the area with beautiful, durable concrete floors that exceed expectations. From initial consultation through final sealing, we handle every detail with precision and care.

Ready to explore what concrete flooring can do for your space? Designer Concrete Palm Beach is here to help you create the floor of your dreams—one that combines stunning aesthetics with practical performance for years to come.

Ready to Transform Your Space with Concrete Flooring?

Let our concrete flooring specialists create stunning, durable floors that enhance your space's beauty and value. Contact us today for a free consultation and estimate. Visit our homepage to explore all our concrete services.