Table of Contents

▶In This Guide

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

Polished Concrete Flooring Contractor in Palm Beach | Designer Concrete

Designer Concrete Palm Beach is a polished concrete flooring contractor serving Palm Beach with durable, low-maintenance floor solutions. Polished concrete floor companies transform existing concrete into glossy, seamless surfaces that resist stains, reduce dust, and last decades. The process involves grinding, densifying, and polishing concrete in multiple stages, typically completed within 3-5 days depending on space size and desired finish level. This is one of our most popular decorative concrete services and a key component of our luxury concrete offerings. For specialized expertise, consider our concrete flooring specialist services.

Looking for a polished concrete flooring contractor who actually delivers on those Pinterest-worthy floors you've been dreaming about? Designer Concrete Palm Beach specializes in transforming dull, worn concrete into sleek, high-gloss surfaces that look stunning and stand up to whatever life throws at them. Whether you're upgrading your home, renovating a commercial space, or starting from scratch, our polished concrete installations combine serious durability with that modern, industrial-chic aesthetic everyone wants. Our experienced concrete contractors have mastered this specialized technique. For professional floor installations, consider our concrete floor contractor services.

Ready to see what polished concrete can do for your space? View our project videos to see polished concrete transformations. Call us today at +1 561-248-0274 for a free consultation.

What Makes Polished Concrete Different?

Here's the thing about polished concrete—it's not just concrete with a shiny coating slapped on top. We're talking about a multi-step grinding and polishing process that literally transforms the concrete itself into a smooth, reflective surface.

Think of it like this: we start with your existing concrete slab (or a fresh pour) and use progressively finer diamond-grinding tools to smooth out imperfections, open up the aggregate, and create that signature polished look. Then we apply a densifier that hardens the concrete from within, making it incredibly tough. The final polishing steps bring out that glass-like shine.

And the result? A seamless floor with depth, character, and a finish level you can actually choose—from a subtle satin to a full mirror-like reflection.

Why Choose Designer Concrete Palm Beach for Your Polished Concrete Floor?

We've been polishing concrete floors throughout Palm Beach County for years, and honestly, we've gotten pretty good at it. But more importantly, we've learned what actually matters to homeowners and business owners who are making this investment.

Local expertise that matters.

Living in South Florida means dealing with humidity, occasional flooding, and concrete that behaves differently than it does up north. We know how to work with the unique conditions here—from proper moisture testing to choosing the right densifiers for our climate.

No cookie-cutter approaches.

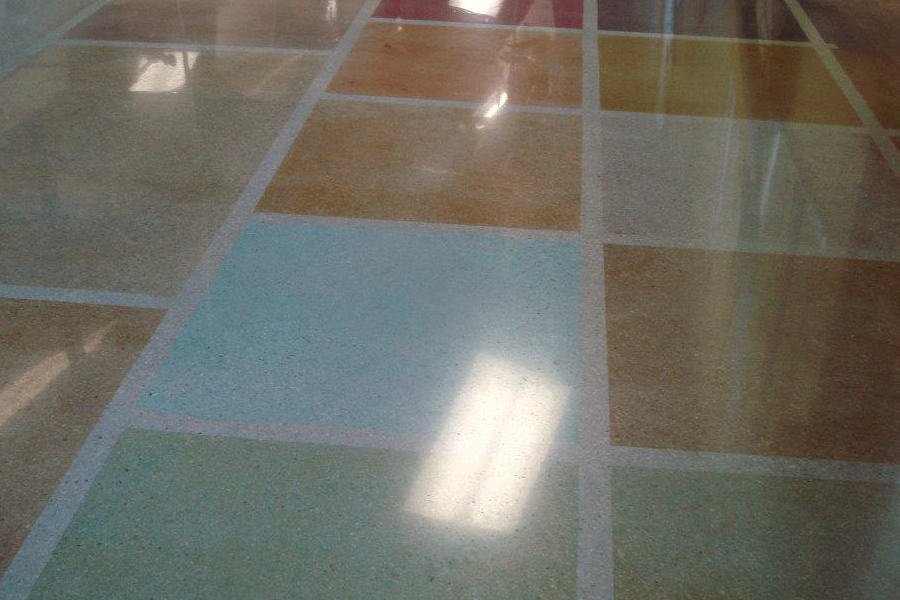

Your concrete is unique, and your needs are too. Maybe you want to highlight the natural aggregate for a terrazzo-like effect. Or maybe you prefer a smooth, uniform finish. We customize our process to match your vision and your space's specific requirements.

We stand behind our work.

Every polished concrete floor we install comes with a written warranty covering both materials and workmanship. If something's not right, we make it right. Period.

Transparent process, no surprises.

We walk you through exactly what's going to happen, how long it'll take, and what it'll cost before we start grinding. No hidden fees, no scope creep, no "oh, we didn't realize we'd need to do that" conversations later.

Benefits of Professional Polished Concrete Flooring

Here's what you're actually getting when you invest in professionally polished concrete:

- •Insane durability – We're talking 20+ years of reliable performance with minimal maintenance. Polished concrete floor companies see these surfaces outlast virtually every other flooring option available.

- •Almost zero maintenance – Sweep it, mop it occasionally, and you're done. No waxing, no refinishing, no special treatments. Just a floor that keeps looking good.

- •Major cost savings over time – Yeah, the upfront investment is real. But when you factor in what you'd spend replacing carpet, refinishing hardwood, or re-tiling over two decades? Polished concrete wins. Every time.

- •Better air quality – No grout lines trapping dirt and mold. No carpet fibers holding allergens. Just a smooth, sealed surface that doesn't harbor the stuff that makes people sneeze.

- •Light reflectivity that's actually useful – That polished surface bounces light around your space, reducing the need for artificial lighting during the day. Lower electric bills and a brighter room? Yes, please.

- •Moisture resistance built in – Once we densify and polish your concrete, water just sits on top until you wipe it up. No absorption, no staining, no problem.

- •Customizable appearance – From exposed aggregate to smooth and sleek, from natural gray to colored concrete, you've got options. Lots of them.

Our Polished Concrete Process

We've refined this process over hundreds of floors. Here's exactly what happens:

1. Assessment and Prep (Day 1)

We evaluate your concrete's condition, check for moisture issues, repair any cracks or damage, and make sure the surface is ready for grinding. This step is crucial—rushing it means problems later.

2. Coarse Grinding (Day 1-2)

Using diamond-grinding equipment, we remove any existing coatings, smooth out the surface, and start revealing the aggregate underneath (if that's the look you want). This is the loudest, dustiest part of the job, but our equipment captures most of the dust.

3. Densifier Application (Day 2)

We apply a chemical densifier that penetrates the concrete and triggers a reaction that makes it significantly harder and less porous. This is what gives polished concrete its legendary durability.

4. Fine Grinding and Polishing (Day 2-3)

Multiple passes with progressively finer diamond pads bring out the shine. We work our way up to your chosen finish level—from a low-gloss satin to a high-gloss mirror finish.

5. Sealer Application (Day 3-4)

A protective sealer goes on to guard against staining and make cleaning even easier. Then we let it cure properly before you move furniture back in.

6. Final Walkthrough

We don't consider the job done until you're completely satisfied. We walk through the space together, answer any questions about care and maintenance, and make sure everything meets your expectations.

Most residential projects take 3-5 days from start to finish, depending on the size and condition of your floor.

Polished Concrete Applications

This isn't just for industrial warehouses anymore. We install polished concrete in:

Residential spaces

Living rooms, kitchens, basements, home offices, even bedrooms. The clean, modern look works beautifully in contemporary homes.

Commercial facilities

Retail stores, restaurants, offices, showrooms. Places where durability and appearance both matter.

Garages and workshops

Where you actually need a floor that can handle dropped tools, oil spills, and heavy equipment without breaking a sweat.

Outdoor patios and covered areas

With the right sealer, polished concrete works great in covered outdoor spaces where you want that seamless indoor-outdoor flow.

Each application requires slightly different approaches, and we adjust our process accordingly.

What Affects Polished Concrete Pricing?

Let's talk numbers. Most polished concrete installations in Palm Beach run between $5-12 per square foot, depending on several factors:

Current floor condition

Starting with clean, smooth concrete costs less than working with a floor that needs extensive repairs or has multiple coatings to remove.

Desired finish level

A basic polish with no exposed aggregate costs less than a high-gloss finish with maximum aggregate exposure.

Square footage

Larger spaces generally cost less per square foot than smaller projects.

Color or stain additions

Adding integral color or acid staining increases cost but creates unique effects.

We provide free on-site estimates that account for your specific situation. No guesswork, no ballpark figures that turn out to be completely wrong. Just an honest assessment of what your project will actually cost.

Serving Palm Beach County

Designer Concrete Palm Beach proudly serves homeowners and businesses throughout Palm Beach County, including West Palm Beach, Palm Beach Gardens, Jupiter, Wellington, Boynton Beach, Delray Beach, and surrounding areas. Our local presence means faster response times and a team that understands South Florida construction and climate considerations.

Frequently Asked Questions About Polished Concrete

How long does polished concrete last?

With proper installation and reasonable care, you're looking at 20+ years of reliable service. Many commercial polished concrete floors are still going strong after 30+ years. It's genuinely one of the most permanent flooring solutions available.

Is polished concrete slippery when wet?

Not as much as you'd think. The texture created during grinding actually provides decent traction, even with a high-gloss finish. For areas where slip resistance is critical, we can adjust our polishing process or add a slip-resistant sealer.

Can you polish my existing concrete floor?

Usually, yes. As long as your concrete is structurally sound and at least 28 days old (for new pours), we can typically polish it. We'll need to assess it first to check for moisture issues or damage that needs addressing.

What's the maintenance like?

Incredibly simple. Sweep or vacuum regularly to remove grit that could scratch the surface. Mop with a pH-neutral cleaner when needed. Re-seal every few years depending on traffic. That's it.

Ready to Transform Your Space with Polished Concrete?

Look, we get it—choosing a polished concrete flooring contractor is a big decision. You're making a significant investment, and you want it done right the first time.

That's exactly what we do. No shortcuts, no compromises, just professional polished concrete installation from a team that's done this hundreds of times.

Call Designer Concrete Palm Beach today at +1 561-248-0274 to schedule your free consultation and estimate. We'll assess your space, answer all your questions, and give you an honest quote with no pressure or sales games. Most projects can start within 2-3 weeks of approval.

Your floor is waiting. Let's make it happen.

Ready to Transform Your Space with Polished Concrete?

Contact us today for a free consultation and discover how we can transform your space with professional polished concrete flooring. Visit our homepage to explore all our concrete services.