Pool Deck Resurfacing West Palm Beach: Complete Guide

Pool deck resurfacing west palm beach is the process of applying a new surface layer over existing concrete pool decks to repair damage, improve appearance, and enhance safety. In West Palm Beach, resurfacing typically costs between $3-$8 per square foot, significantly less than complete replacement. The process involves cleaning and repairing the existing surface, applying a concrete overlay or specialized coating, and finishing with slip-resistant, heat-reflective materials ideal for Florida's climate. Professional resurfacing services by Designer Concrete Palm Beach take 2-5 days to complete and can extend your pool deck's lifespan by 10-15 years while transforming cracked, faded surfaces into beautiful, functional outdoor spaces. Learn more about concrete West Palm Beach services.

Table of Contents

▶In This Guide

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

- 11.

- 12.

Pool Deck Resurfacing West Palm Beach: Transform Your Worn Concrete

Your pool deck's seen better days, hasn't it? Cracks spreading across the surface. Faded spots where the Florida sun's done its damage. Maybe it's getting rough underfoot, or worse—slippery when wet.

Here's the good news: you don't need to rip everything out and start from scratch. Pool deck resurfacing West Palm Beach homeowners choose from Designer Concrete Palm Beach brings tired concrete back to life at a fraction of replacement costs. We're talking about a complete transformation in just a few days, not weeks.

And honestly? The results speak for themselves.

What Exactly Is Pool Deck Resurfacing?

Think of it as a facelift for your concrete. We apply a new surface layer right over your existing deck—covering up the damage, sealing out moisture, and giving you a fresh canvas to work with.

The process fixes cracks, smooths out rough patches, and lets you completely redesign how your pool area looks. Want a stone pattern? We can do that. Prefer a cool-to-the-touch texture in a custom color? Done.

Best part? Your old concrete becomes the foundation. No demolition. No hauling away tons of debris. Just a beautiful new surface that's built to last.

Why Pool Decks Fail in South Florida

Let's be real—our climate is brutal on concrete. Between the heat, humidity, and all that pool water (not to mention the chemicals), your deck takes a beating year-round.

You've probably noticed the telltale signs. Surface cracks that start small and spread. Discoloration where the concrete's weathered unevenly. Rough spots that weren't there before. Standing water that never seems to drain quite right.

Here's what's actually happening underneath: the concrete's breaking down. UV rays deteriorate the surface. Chlorine eats away at the finish. Water seeps into tiny cracks, expands when it heats up, and makes those cracks bigger. It's a cycle that only gets worse with time.

But resurfacing stops that cycle cold.

Benefits of Professional Pool Deck Resurfacing

Safety comes first. Worn concrete develops uneven surfaces and sharp edges. Our resurfacing creates a smooth, slip-resistant finish that protects bare feet and prevents accidents. Especially important if you've got kids running around.

Your property value jumps. Buyers notice pool areas immediately. A worn, cracked deck screams "maintenance headache." A freshly resurfaced deck with modern finishes? That's a selling point.

You'll actually save money. Complete deck replacement runs $15-25 per square foot in West Palm Beach. Resurfacing? Usually $3-8 per square foot, depending on the finish you choose. That's serious savings.

The look is completely customizable. We're not just patching cracks here. You can change colors, add patterns, create borders—whatever matches your vision for the space.

It lasts. Quality resurfacing with proper sealing gives you 10-15 years of beautiful, durable performance. And when it eventually needs attention again, you can resurface right over it.

Fast turnaround means less disruption. Most projects wrap up in 3-5 days. Compare that to tearing out and replacing a deck, which can take weeks and turn your backyard into a construction zone.

Our Pool Deck Resurfacing Options in West Palm Beach

We've installed hundreds of pool decks across Palm Beach County. Here's what works.

Concrete Overlay Systems

The foundation of most resurfacing projects. We apply a thin layer of specialized concrete (usually 1/8 to 1/4 inch) over your existing deck. This covers minor damage, creates a fresh surface, and gives us the perfect base for decorative finishes.

Overlays come in different formulations. Some are designed for maximum strength. Others focus on flexibility to handle slight movements in the concrete. We match the product to your specific situation.

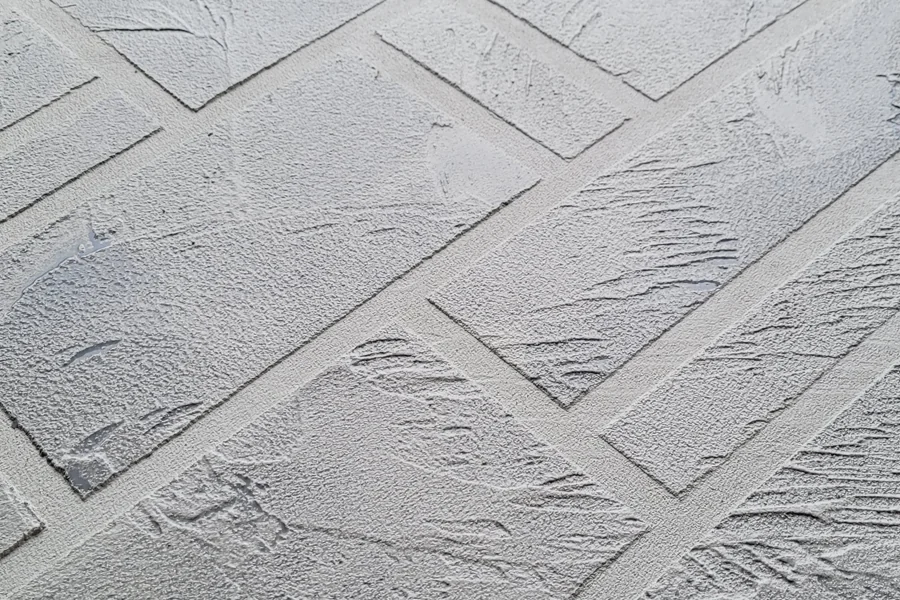

Stamped Concrete Finishes

Want the look of natural stone without the price tag? Stamped concrete's your answer.

We press patterns into the fresh overlay to mimic slate, flagstone, brick, tile—even wood planks. The detail is remarkable. Most people can't tell it's concrete until they touch it.

Popular patterns for pool decks around here include:

- Arizona flagstone (irregular, natural-looking stone)

- European cobblestone (old-world charm)

- Slate texture (modern and sophisticated)

- Travertine (classic pool deck aesthetic)

The pattern's just the start. We add color variations to make it look even more authentic.

Decorative Concrete Staining

Color transforms everything. We offer acid-based stains that react with the concrete chemically, creating rich, variegated tones that penetrate deep. Or water-based stains for brighter, more consistent colors.

Earth tones work beautifully in South Florida—think warm browns, tans, and terra cottas that complement tropical landscaping. But we've also done stunning work with blues, grays, and even multi-color designs.

The color won't peel, chip, or fade. It's in the concrete, not on top of it.

Cool Deck and Textured Coatings

Here's something people ask about constantly: "Won't the new surface be hot in summer?"

Not if we design it right. We apply specialized coatings that reflect heat and stay significantly cooler than standard concrete. You can walk barefoot comfortably, even on 95-degree days. For even better heat resistance, consider pebble pool deck surfaces which naturally stay cooler.

These coatings also provide excellent slip resistance—crucial for pool safety. The texture gives your feet something to grip, wet or dry.

Crack Repair and Structural Work

Before we resurface anything, we assess what's underneath. Are the cracks just cosmetic, or is there a deeper issue? Is the concrete settling? Are tree roots causing problems?

We fix structural issues first. Stabilize settling sections. Reroute drainage if needed. Fill and seal cracks properly. Because here's the thing—if you just cover up problems without addressing them, they'll come back. We do it right the first time.

How We Transform Your Pool Deck

Our process is pretty straightforward, but the details matter.

Step 1: We Evaluate Your Deck

First visit, we're looking at the concrete's condition, taking measurements, checking for drainage issues, and discussing what you want the finished deck to look like. We'll show you samples, talk through options, and give you a detailed quote.

No pressure. Just information so you can make the right decision.

Step 2: Prep Work Makes the Difference

This is where quality companies separate themselves from the rest. We clean the surface thoroughly—pressure washing, degreasing, removing any coatings or sealers that would prevent bonding.

We repair cracks and damage. Grind down any high spots. Make sure the surface is perfectly prepared to accept the new overlay.

Most problems with resurfacing jobs? They trace back to poor prep work. We don't skip steps.

Step 3: Application

Our crews apply the overlay material, working in sections to maintain consistent thickness. If you're getting stamped patterns, we press those in while the concrete's still workable—timing is everything.

For stained finishes, the color application happens once the overlay's cured. Multiple coats, carefully blended to achieve the look you wanted.

Step 4: Sealing and Protection

The final step protects your investment. We apply a high-quality sealer that guards against moisture, chemicals, UV damage, and staining. The sealer also enhances the color and adds a subtle sheen.

Then we let it cure properly. Rushing this part ruins everything else we've done right.

Step 5: Walkthrough and Care Instructions

We show you the finished deck, answer any questions, and explain how to maintain it. Simple stuff—occasional cleaning, resealing every few years. Nothing complicated.

Why Choose Designer Concrete Palm Beach?

Look, there are plenty of contractors in West Palm Beach. Here's why we're different.

We specialize in decorative concrete.

This isn't a side service for us—it's what we do, day in and day out. Our crews have years of experience specifically with overlays, stamping, and staining. The quality shows in the details.

We use commercial-grade materials.

Florida's tough on concrete. We only use products engineered for our climate, from suppliers who stand behind their warranties. No shortcuts.

We're actually local.

Our office is right here in West Palm Beach. We've worked on properties from Palm Beach Gardens down to Wellington and everywhere in between. We know the area, we know the challenges, and we're here after the job's done.

Our reputation matters to us.

Most of our work comes from referrals and repeat customers. We've built that reputation by showing up when we say we will, doing exactly what we promised, and backing up our work with real warranties.

Transparent pricing, no surprises.

The quote we give you is what you'll pay. No hidden fees, no change orders for things we "discovered" halfway through. We figure it out upfront.

When Should You Resurface Your Pool Deck?

Here are the signs we see most often:

Visible cracking—not just hairline cracks, but ones that are spreading or getting wider. Surface spalling, where chunks of concrete are flaking off. Rough, deteriorated texture that's uncomfortable to walk on. Stains that won't come out no matter what you try.

But sometimes it's just cosmetic. The concrete's structurally fine, you're just tired of looking at it. That's a perfectly good reason to resurface too.

Generally speaking, if your pool deck is more than 10-15 years old and showing wear, resurfacing makes sense. Waiting too long means the damage gets worse, and more extensive (read: expensive) repairs become necessary.

Frequently Asked Questions

How long does pool deck resurfacing take?

Most residential decks take 3-5 days from start to finish. Day one is prep work. Days 2-3 are application and decorative work. Day 4 is sealing. Day 5 might be a buffer for weather or additional coats. You can usually start using the deck 48-72 hours after we finish, though we recommend waiting a full week before heavy furniture or pool parties.

Will the new surface crack like the old one did?

Modern overlay products are more flexible and better engineered than old-school concrete. We also install control joints to manage any movement. Plus, proper sealing prevents water intrusion that causes cracking. Will you eventually see some wear? Sure—nothing lasts forever. But we're talking 10-15 years of great performance with basic maintenance.

Can you resurface around pool coping and drains?

Absolutely. We work carefully around all the existing features—coping, drains, returns, lights. The overlay bonds right up to them, creating clean transitions. In fact, resurfacing often makes these features look better by contrast.

What's the maintenance like?

Pretty simple. Keep it clean—sweep regularly, hose off occasionally. Avoid harsh chemicals (though normal pool water exposure is fine). Reseal every 2-3 years to maintain the protective layer. That's about it. Way less maintenance than natural stone or pavers.

How much does pool deck resurfacing cost in West Palm Beach?

Depends on the finish you choose and the deck's condition. Basic overlay and seal might run $3-5 per square foot. Stamped concrete with multiple colors gets into the $6-10 range. We provide detailed quotes after seeing your specific situation—too many variables to quote over the phone.

Serving West Palm Beach and Palm Beach County

We're proud to serve homeowners and businesses throughout the area, including Palm Beach Gardens, Jupiter, Wellington, Royal Palm Beach, Boynton Beach, and Lake Worth.

Local knowledge matters with concrete work. We understand how the sandy soil affects settling. We know which finishes hold up best in coastal areas with salt air. We're familiar with local codes and requirements.

Plus, we're right here if you ever need us down the road. Call us, and we'll come take a look—no service call charges for past customers.

Ready to Transform Your Pool Deck?

You've got options. Keep dealing with that worn, cracked concrete. Or invest a few days and a reasonable budget into pool deck resurfacing West Palm Beach property owners recommend to their neighbors.

The choice is pretty clear, isn't it?

Contact Designer Concrete Palm Beach today for a free consultation and detailed estimate. We'll come to your property, assess the situation, show you samples of different finishes, and explain exactly what we can do.

No pressure. Just honest advice from people who do this work every single day.

Designer Concrete Palm Beach

Website: https://designerconcretepalmbeach.com/

Serving West Palm Beach and all of Palm Beach County

Ready to Transform Your Pool Deck?

Contact Designer Concrete today for a free consultation and discover how our pool deck resurfacing services can enhance your outdoor living space. See examples of our work in our project videos. Visit our homepage to explore all our concrete services.